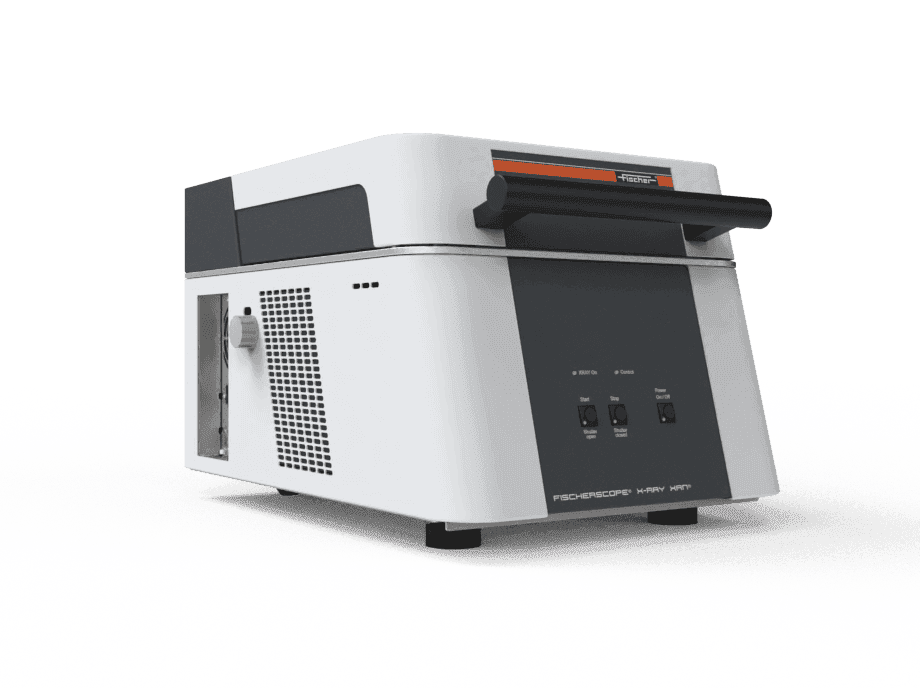

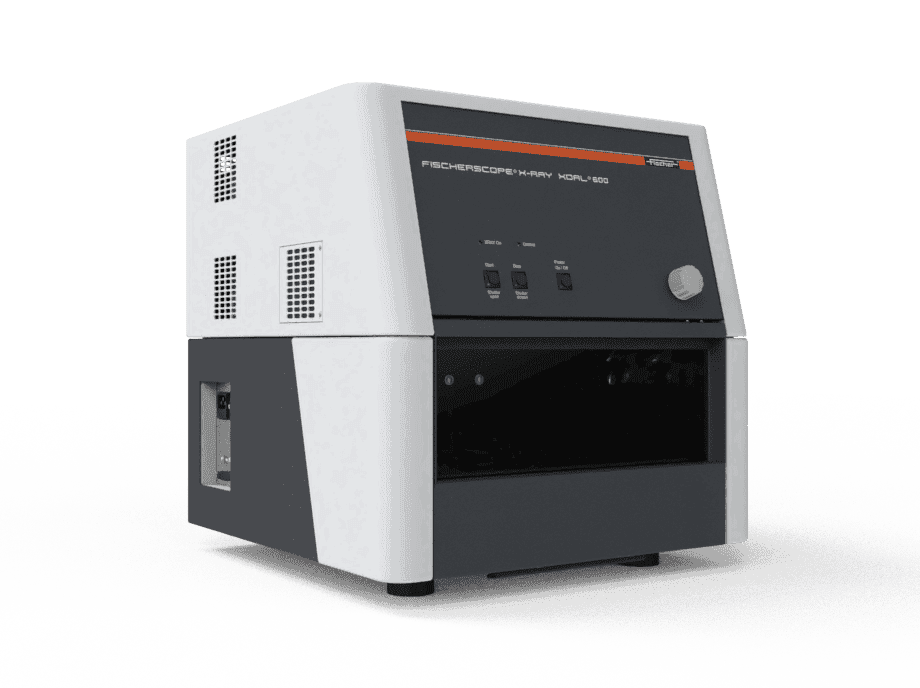

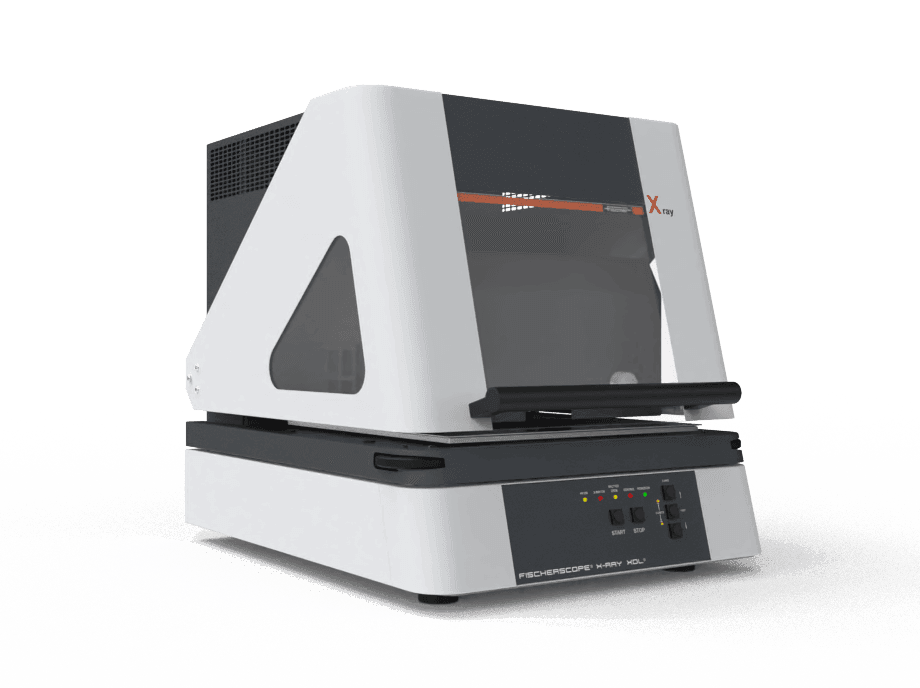

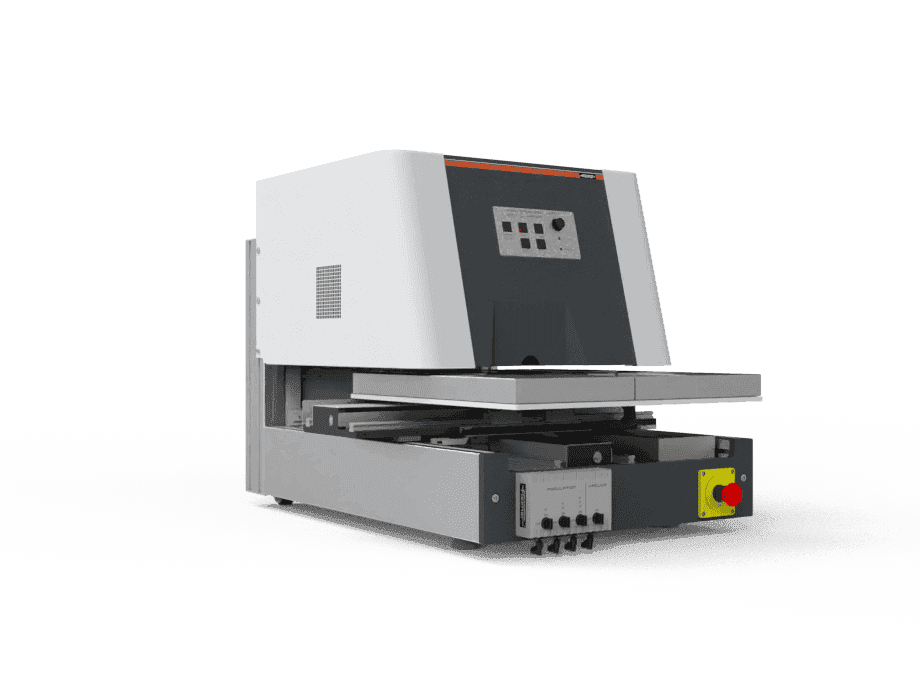

FISCHERSCOPE® X-RAY XDV®-µ WAFER

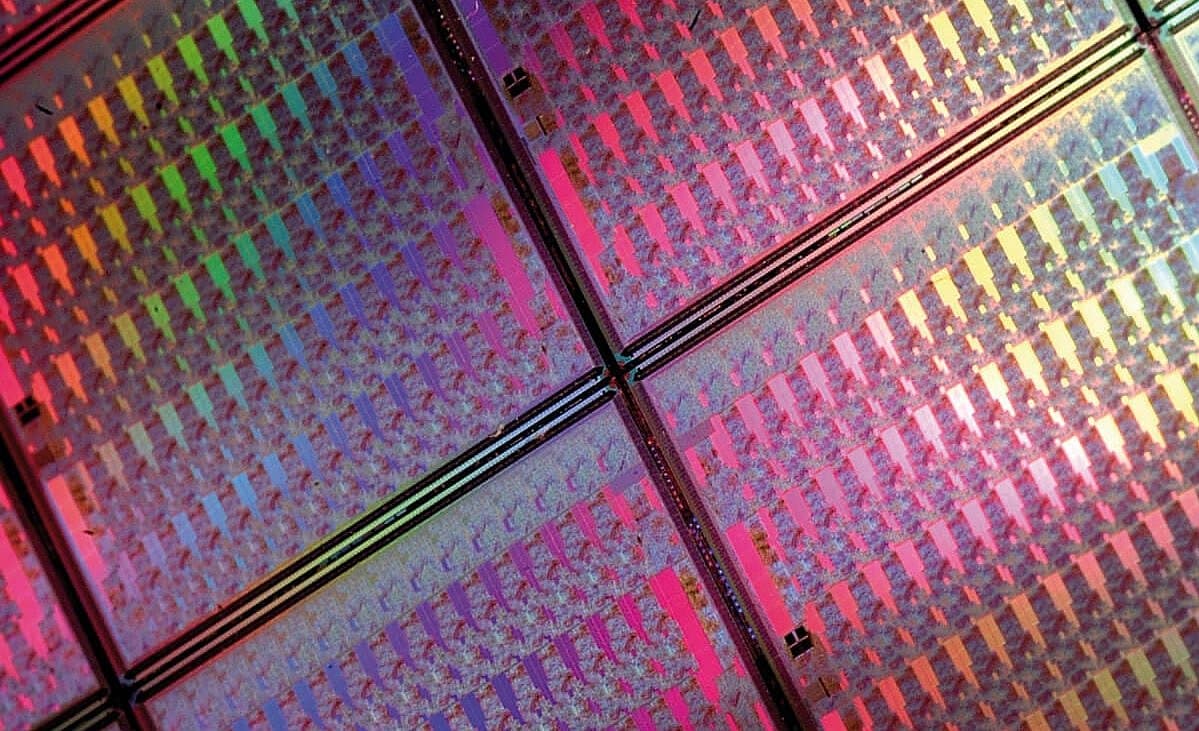

Cutting-edge technology for wafer applications.

Special equipment for automated measurements of thin films and multilayer systems on wafers with diameters from 6 - 12 inches.

Key Benefits

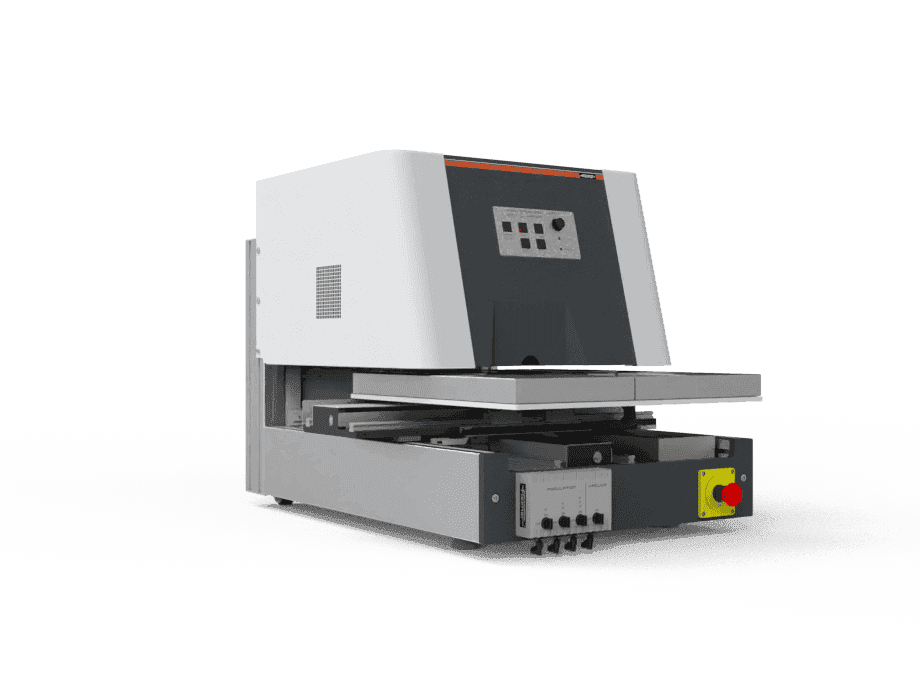

- Fully integrated solution.: XDV®-μ SEMI combined with wafer handler of your choice

- Programmable.: Automated measurements on predefined structures thanks to advanced pattern recognition technology

- Meeting all challenges.: Reliable and fast results for ambitious measuring tasks

- Fully automatable.: Let your instrument work for you with just one click

Description

Special equipment for automated measurements of thin films and multilayer systems on wafers with diameters from 6 - 12 inches.

¹ Up to 50 % increased performance: Significantly improved standard deviation and thus gauge capability or significantly reduced measurement time compared DPP to DPP+. ² High-end capillary optics made by Fischer – the world's only manufacturer of X-ray fluorescence measuring instruments with its own polycapillary production. Three different high-end polycapillaries available – the right solution for each of your applications: 10 µm halo-free, 20 µm halo-free or 20 µm halo.

Due to the programmable measuring table with vacuum wafer chuck and microfocus tube Ultra, the FISCHERSCOPE® X-RAY XDV®-µ WAFER is optimally tailored to the needs of the semiconductor industry. Polycapillary optics built into the XRF device concentrate the X-ray radiation on smallest measuring spots of 10 or 20 µm for short measuring times at high intensity. This allows you to analyze individual microstructures much more precisely than with conventional devices - and completely automated.

XDV®-μ SEMI combined with wafer handler of your choice

Automated measurements on predefined structures thanks to advanced pattern recognition technology

Reliable and fast results for ambitious measuring tasks

Let your instrument work for you with just one click

Our in-house manufactured polycapillary optics deliver outstanding measurement results at short measuring times

Shorter measuring times or improvement of standard deviation*

*compared to the DPP

Microfocus tube Ultra with tungsten anode for even higher performance on smallest spots with µ-XRF; Molybdenum anode optional

DPP+ for highest precision even with short measuring times

4-fold changeable filter

In-house manufactured polycapillary optics allow especially small measuring spots with high intensity

Measuring spot approx.: Ø 10 or 20 µm (FWHM)

Up to 5 mm possible height of samples

Silicon drift detector with 20 or 50 mm² for highest precision on thin layers

Vacuum table with holders for all standard wafer formats from 150 - 300 mm

Extensive options for automation with WinFTM®

Do you have further applications? Then contact us!

Features

- Microfocus tube Ultra with tungsten anode for even higher performance on smallest spots with µ-XRF; Molybdenum anode optional

- DPP+ for highest precision even with short measuring times

- 4-fold changeable filter

- In-house manufactured polycapillary optics allow especially small measuring spots with high intensity

- Measuring spot approx.: Ø 10 or 20 µm (FWHM)

- Up to 5 mm possible height of samples

- Silicon drift detector with 20 or 50 mm² for highest precision on thin layers

- Vacuum table with holders for all standard wafer formats from 150 - 300 mm

- Extensive options for automation with WinFTM®

- Fischer DPP+ ¹ for highest precision even with short measuring times

- Polycapillary optics produced in-house² with smallest spot size 10 µm (FWHM)

- Automatic image recognition for reliable measuring of small structures

- Measuring of smallest structures on wafers up to 12 inch diameter

- Analysis of very thin coatings, such as gold/palladium layers down to < 10 nm

- Automated measuring such as in quality control

- Determination of complex multilayer systems