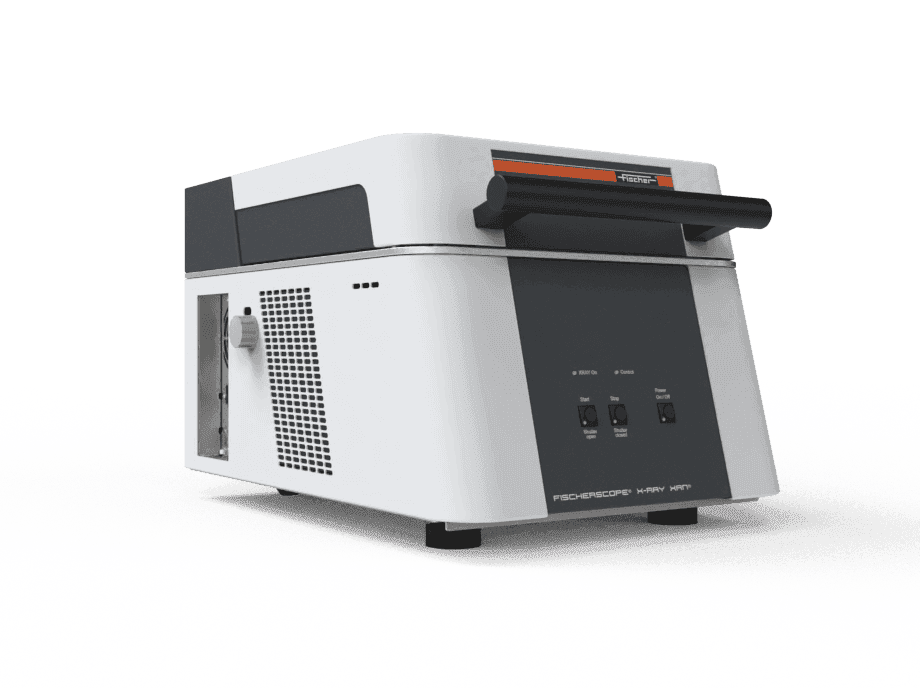

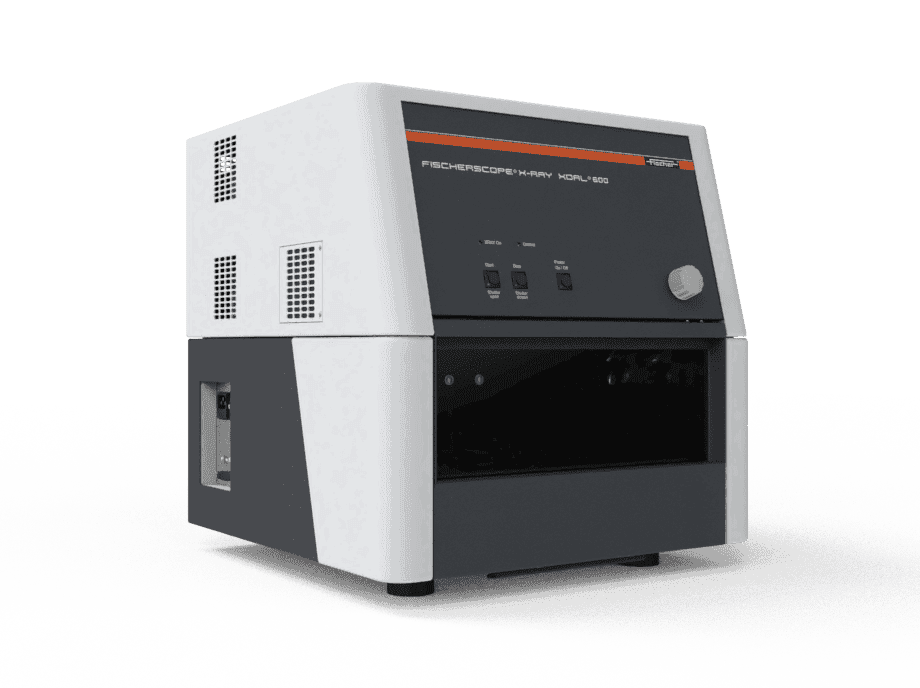

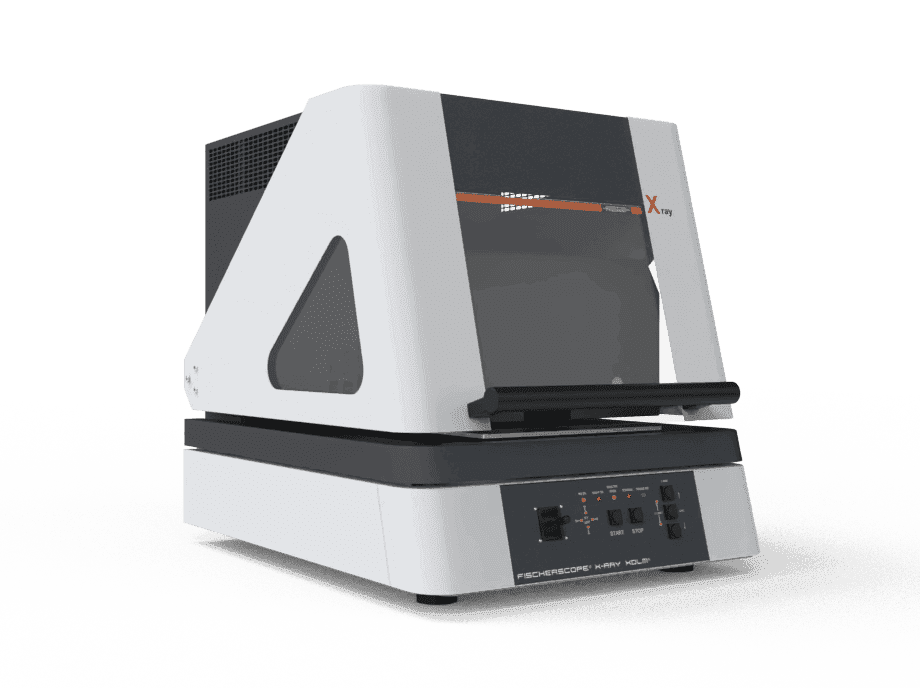

FISCHERSCOPE® X-RAY XDLM®

Your entry into automated measuring.

Universal instrument for inspection of small parts and small structures, measuring of light metals, hard coatings and thin electroplated parts.

Key Benefits

- Commissioning.: Extremely fast and simple

- Tailor-made.: Different models offer the optimal solution for your application

- Testing of multiple measuring points.: Even with large samples, measuring points are possible on the entire sample surface

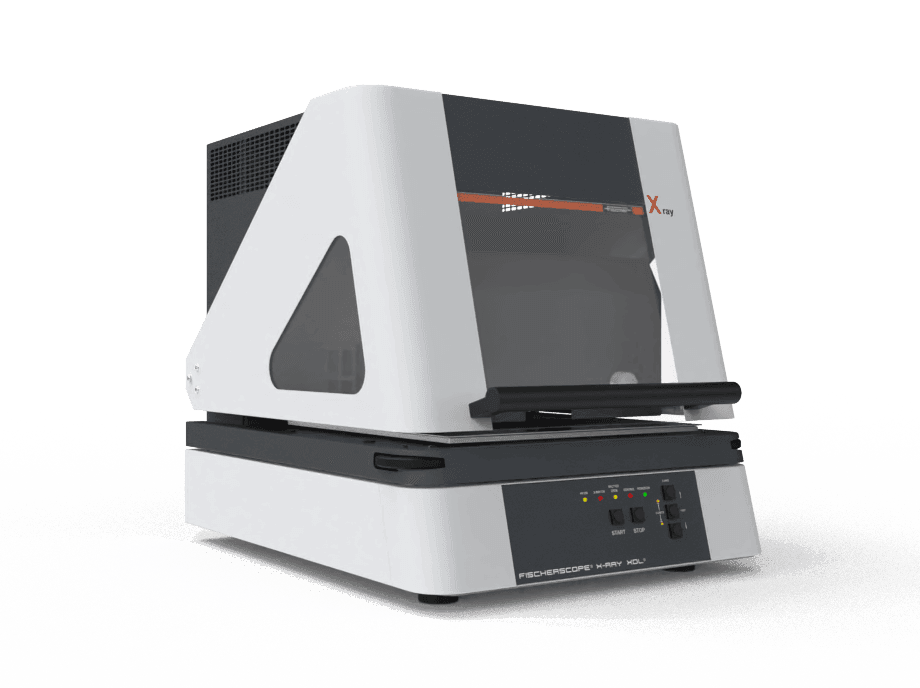

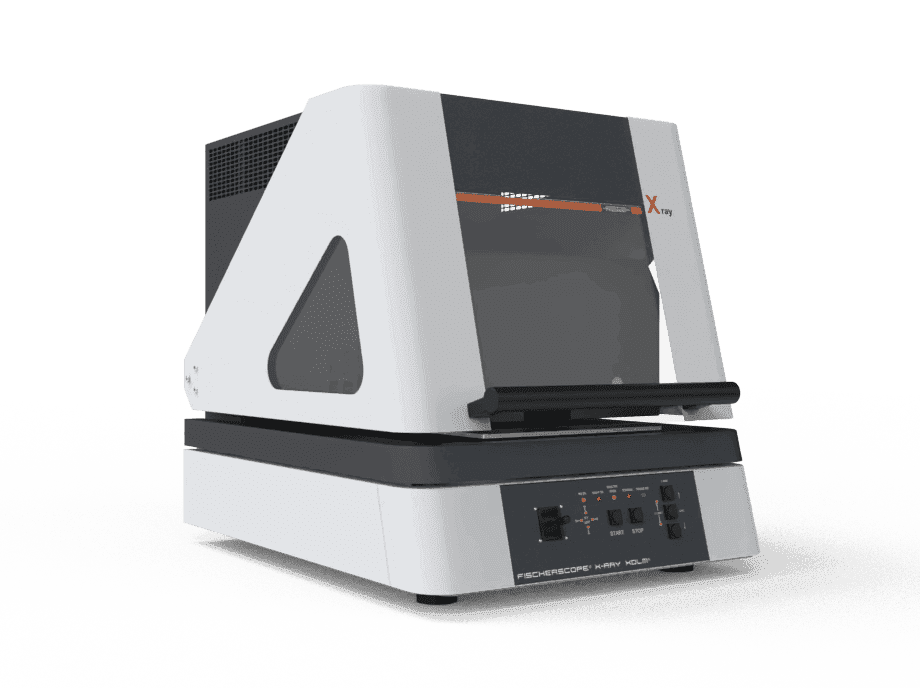

- Also for large samples.: Hood with C-slot

Description

Universal instrument for inspection of small parts and small structures, measuring of light metals, hard coatings and thin electroplated parts.

Equipped with a microfocus tube, multiple aperture and primary filter changer, the XDLM® series is the best choice to inspect many small parts one after the other. The instruments are closely related to the XULM® series, with only one significant difference: measuring direction from top down! This means: convenient analysis of uneven samples as well as the possibility of automated measuring and therefore predestined for quality assurance, incoming goods inspection and production monitoring. As a special solution for PCBs, the device is available as XDLM® PCB.

Extremely fast and simple

Different models offer the optimal solution for your application

Even with large samples, measuring points are possible on the entire sample surface

Hood with C-slot

Robust design for measurement on mass parts

The sample is placed and ready for measurement in just a few steps

Microfocus tube

Proportional counter tube detector for short measuring times and small measuring spots

Up to 140 mm possible height of samples

4-fold changeable apertures

Smallest measuring spot approx.: Ø 0.1 mm

Determination of metal content in electroplating baths with corresponding accessories

3-fold changeable filters

Various measuring table options

Type approved full protection device

Do you have further applications? Then contact us!

Features

- Microfocus tube

- Proportional counter tube detector for short measuring times and small measuring spots

- Up to 140 mm possible height of samples

- 4-fold changeable apertures

- Smallest measuring spot approx.: Ø 0.1 mm

- Determination of metal content in electroplating baths with corresponding accessories

- 3-fold changeable filters

- Various measuring table options

- Type approved full protection device

- Adjustment of the measuring distance through patented DCM method

- Type approved full protection device

- PC-detector with largest measuring window on the market

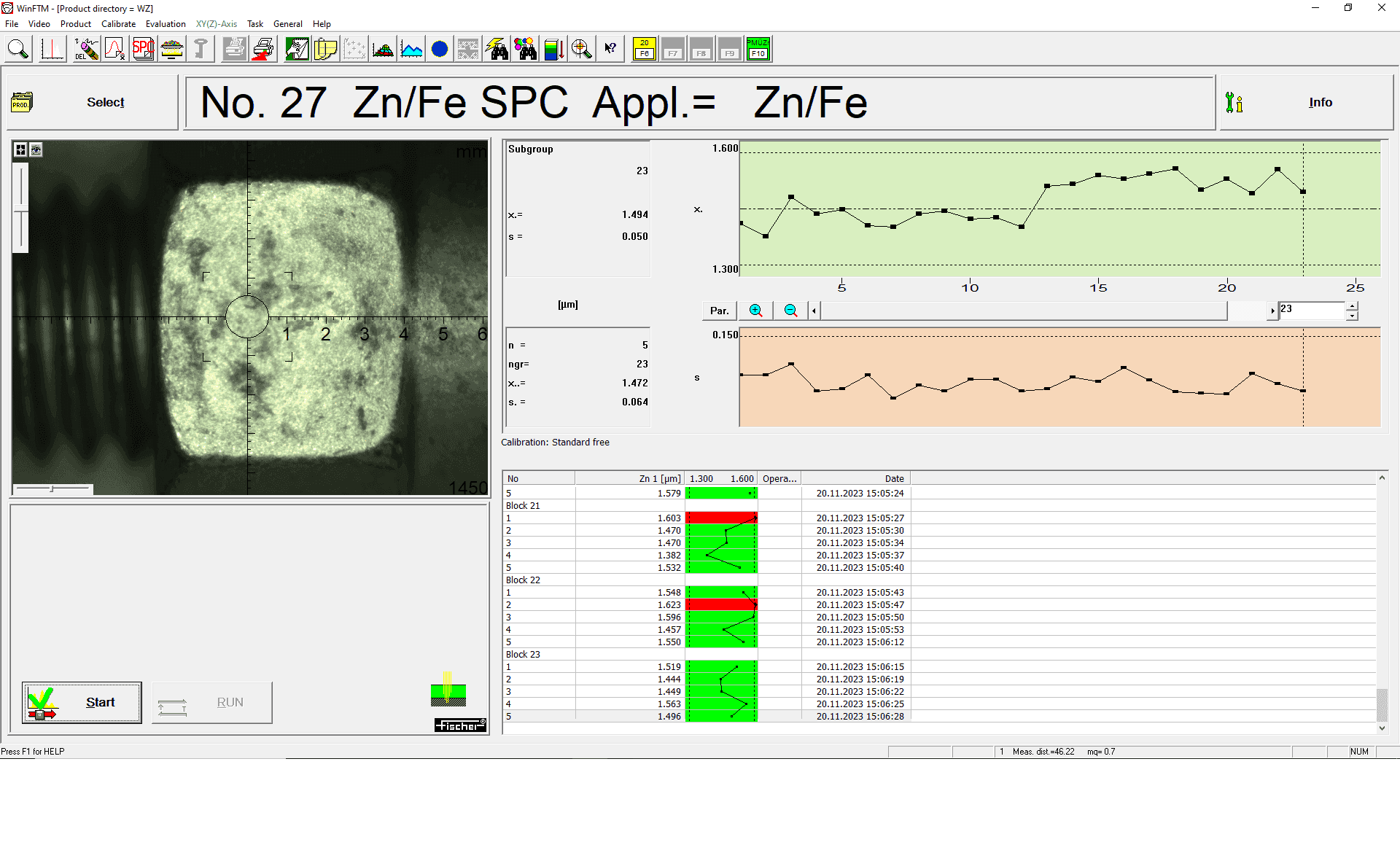

- Electroplated coatings such as zinc on iron as corrosion protection

- Serial testing of mass-produced parts

- Compositional analysis of special steels, such as molybdenum detection in A4

- Decorative chromium coatings, e.g. Cr/Ni/Cu/ABS

- All typical chromium coatings - also new ones such as CrVI

- Measuring of functional gold coatings on PCBs such as Au/Ni/Cu/PCB or Sn/Cu/PCB

- Coatings of connectors and contacts in the electronics industry such as Au/Ni/Cu and Sn/Ni/Cu

- Determination of the metal content of electroplating baths

Documents

- AN059 Determining coating thickness on PVD-coated tools0.47 MB

- AN072 Simplifying quality control on PCBs with automatic pattern recognition0.67 MB

- AN076 Material analysis of corrosion resistant fasteners0.95 MB

- AN092 How to choose an XRF instrument1.29 MB

- AN094 XRF analysis with proportional counter tube – These are the advantages0.36 MB

- Product overview: Complete portfolio3.17 MB

- Product overview: FISCHERSCOPE® X-RAY series3.67 MB

Videos

- FISCHERSCOPE® X-RAY XDLM® 237: Introduction

- FISCHERSCOPE® X-RAY: Calibration of X-ray measuring instruments

- FISCHERSCOPE® X-RAY tutorial: Stability test

- FISCHERSCOPE® X-RAY tutorial part 1: Export / Import products in WinFTM®

- FISCHERSCOPE® X-RAY tutorial part 2: Export / Import products in WinFTM®

- FISCHERSCOPE® X-RAY XDLM® 237: Solution analysis of electrolytes – easy & fast

- FISCHERSCOPE® X-RAY XDLM® 237: Programmable, motor-driven XY-stage for automated measurements

- FISCHERSCOPE® X-RAY XDLM® tutorial part 1: Introduction, warm up and reference measurement

- FISCHERSCOPE® X-RAY XDLM® tutorial part 2: Standard free measurements, calibration and normalization

- FISCHERSCOPE® X-RAY XDLM® tutorial part 3: XY programming and pattern recognition