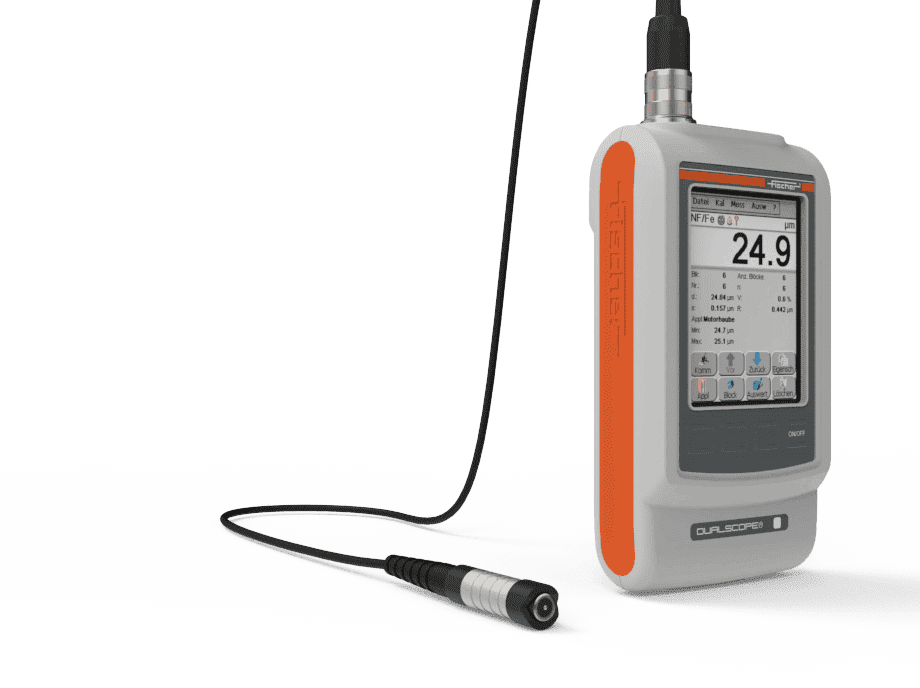

PHASCOPE® PMP10

The classic for the most complex applications.

The most experienced handheld device in our tactile portfolio – reliably solves all special applications.

Key Benefits

- Measurement in just one pass.: Optimize quality processes and save time when measuring paint and zinc coatings

- Your security.: Reliable measurement results on curved measuring surfaces and rough surfaces

- Quick-measure design.: Automatic base material recognition simplifies measurement on steel or aluminum, as probe does not need to be changed

- Predestined for small parts.: Thanks to measurement with the phase-sensitive eddy current test method

Description

The most experienced device in our tactile portfolio – reliably solves all special applications.

The PHASCOPE® PMP10 is ideal for quality control of metal coatings and has clever functions that increase the efficiency of your quality assurance process. In conjunction with the appropriate probe, it enables quick measurement of the thickness of a wide variety of coatings, even on small test parts or in hard-to-reach areas. Even rough surfaces can be tested with absolute precision and reliability using the compact handheld device.

Optimize quality processes and save time when measuring paint and zinc coatings

Reliable measurement results on curved measuring surfaces and rough surfaces

Automatic base material recognition simplifies measurement on steel or aluminum, as probe does not need to be changed

Thanks to measurement with the phase-sensitive eddy current test method

Measuring method: Phase-sensitive eddy current method

Probes available for a wide range of applications

Battery operation and continuous operation via supplied plug-in charger

Measured value memory: 20,000

Data transfer via RS232 interface, optional USB

Measuring range: Depending on coating-base material combination and probe used 1 - 200 µm

Do you have other applications? Then contact us!

Features

- Measuring method: Phase-sensitive eddy current method

- Probes available for a wide range of applications

- Battery operation and continuous operation via supplied plug-in charger

- Measured value memory: 20,000

- Data transfer via RS232 interface, optional USB

- Measuring range: Depending on coating-base material combination and probe used 1 - 200 µm

- Robust and ideal for ambitious measuring tasks

- Unique on the market: Phase sensitive eddy current method

- Own calibration standards for reliable measured values

- Coating thickness measurement of zinc on steel or copper on electroplated steel

- Coatings of nickel on steel and copper on iron or bronze

- Non-ferrous metals on non-conductive substrates, such as copper on PCBs

- Thermally sprayed aluminum (TSA) on steel

- Reliable measurement results with curved geometries, convex and concave measuring points and rough surfaces

- With special probes suitable for plated-through holes in PCBs

- Multilayer systems consisting of individual layers in the micrometer range

Supporting Documents

- AN034 Measuring the copper thickness in plated through-holes on PCBs0.57 MB

- AN044 Determining the thickness of thermally sprayed aluminium (TSA) coatings on stainless steel1.66 MB

- AN047 Measuring the zinc plating on nails with PHASCOPE® PMP100.52 MB

- AN091 Different ways to achieve valid measurement values and optimize measurement performance0.20 MB

- Product overview: Complete portfolio3.17 MB

- Product overview: Tactile measuring devices4.82 MB