FISCHERSCOPE® XAN® LIQUID ANALYZER

Efficient inline solution analysis for electroplating baths.

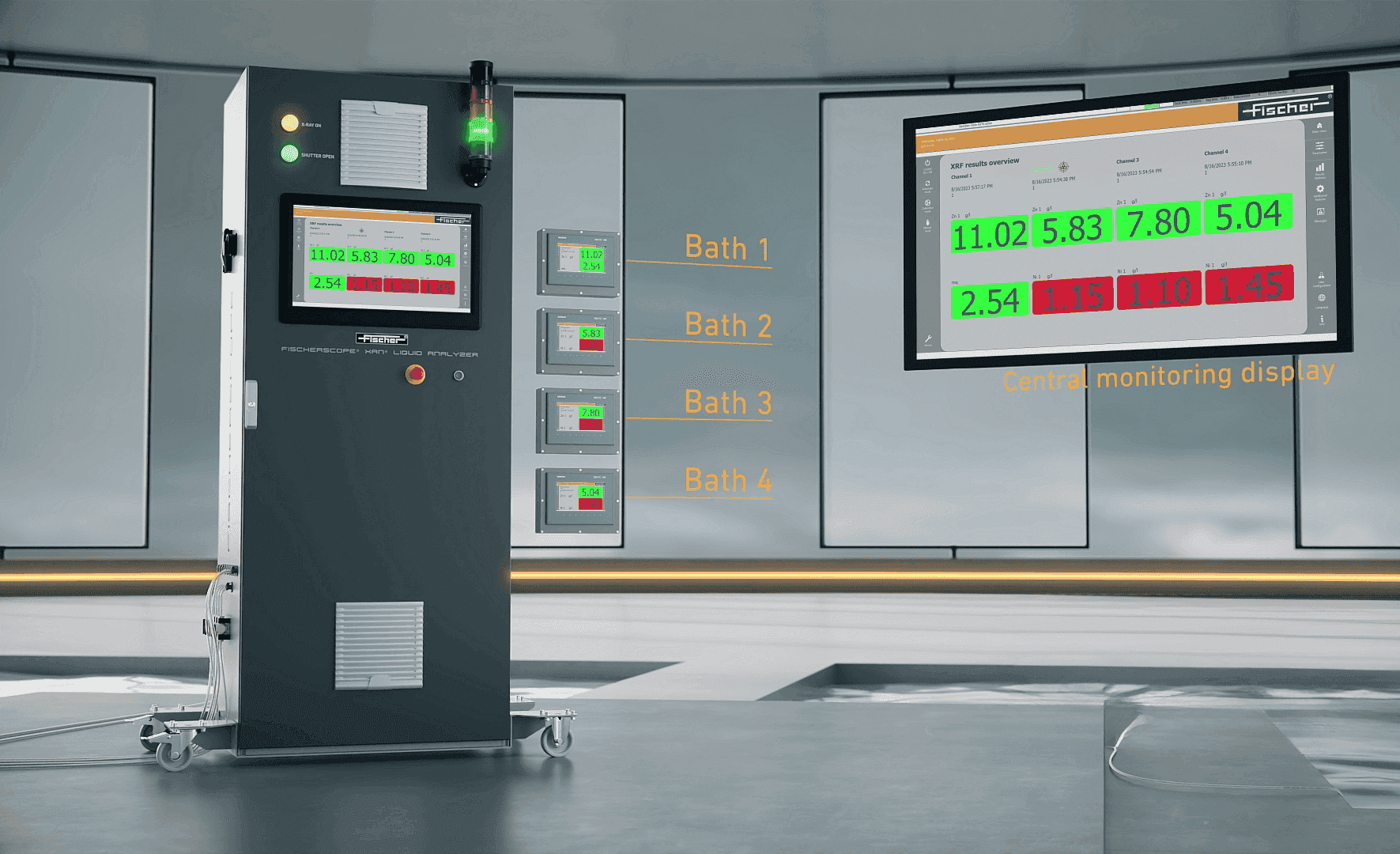

Robust and efficient inline XRF instrument for fully automated analysis of metal concentration of up to 4 galvanic baths.

Key Benefits

- Maximum service life.: High availability of ≥ 1 year* due to innovative design and material selection

- Extremely low maintenance.: Robust construction, service-friendly design

- No time-consuming spot checks and information gaps.: Stay continuously in the picture about your electroplating process

- Absolutely unique.: No need to change* the measuring cell

Description

Robust inline XRF instrument for fully automated analysis of the metal concentration of up to 4 electroplating baths.

¹ In a test setup under controlled laboratory conditions with a typical zinc-nickel solution, a lifetime of the measuring cell of over one year was achieved. The lifetime can vary and is individually dependent on the frequency of the rinsing and cleaning cycles, the composition of the coating baths and their temperatures, and the ambient conditions.

The industry-leading FISCHERSCOPE® XAN® LIQUID ANALYZER is our most recommended XRF analyzer for electroplating baths. Based on the X-ray fluorescence method (XRF), this powerful device enables fully automated and continuous analysis of metal concentrations in your electroplating baths. The unique measuring cell developed in-house, in combination with our powerful XRF software WinFTM®, ensures the best measuring performance and efficient control of your plating system. Thanks to other clever features, you'll benefit from greater process reliability, better coating quality, and reduced costs.

High availability of ≥ 1 year* due to innovative design and material selection

Robust construction, service-friendly design

Stay continuously in the picture about your electroplating process

No need to change* the measuring cell

Live measurement results as well as simple and fast documentation of these

Combination of measuring cell and software ensures best measuring performance and safety

Fully automatic, preventive purging, monitoring and calibration processes ensure maximum uptime

*Depending on, among other things, rinsing and cleaning cycles as well as composition of the plating baths.

Fully automatic sequential measuring of up to 4 plating bath solutions

Microfocus tube with tungsten anode

WAN connectivity

Silicon drift detector 50 mm² for highest precision

1-channel to 4-channel solution

Large and intuitive touchscreen

Higher count rates and significantly reduced measurement times thanks to DPP+

Fieldbus interface

Features

- Fully automatic sequential measuring of up to 4 plating bath solutions

- Microfocus tube with tungsten anode

- WAN connectivity

- Silicon drift detector 50 mm² for highest precision

- 1-channel to 4-channel solution

- Large and intuitive touchscreen

- Higher count rates and significantly reduced measurement times thanks to DPP+

- Fieldbus interface

- No change¹ of the measuring cell necessary

- Long lifetime of the measuring cell of up to 1 year ¹

- Extreme low maintenance and service friendly

- Measuring a variety of metallic bath solutions, such as zinc, nickel, zinc/nickel, gold, silver, chromium, palladium and rhodium

- Other metallic bath solutions on request

Documents

- AN042 Analysis of the metallic content of plating solutions0.64 MB

- AN104 XRF inline solution analysis of the zinc-nickel concentration of galvanic baths4.12 MB

- Flyer: FISCHERSCOPE® XAN® LIQUID ANALYZER6.30 MB

- Product overview: Automated measurement solutions4.91 MB

- Product overview: Complete portfolio3.17 MB

- Product overview: FISCHERSCOPE® X-RAY series3.67 MB

- Technical article Galvanotechnik 04/24: XRF inline solution analysis of the zinc-nickel concentration of galvanic baths0.49 MB