FISCHERSCOPE® X-RAY XDV®-µ SEMI

First choice for automated wafer measuring.

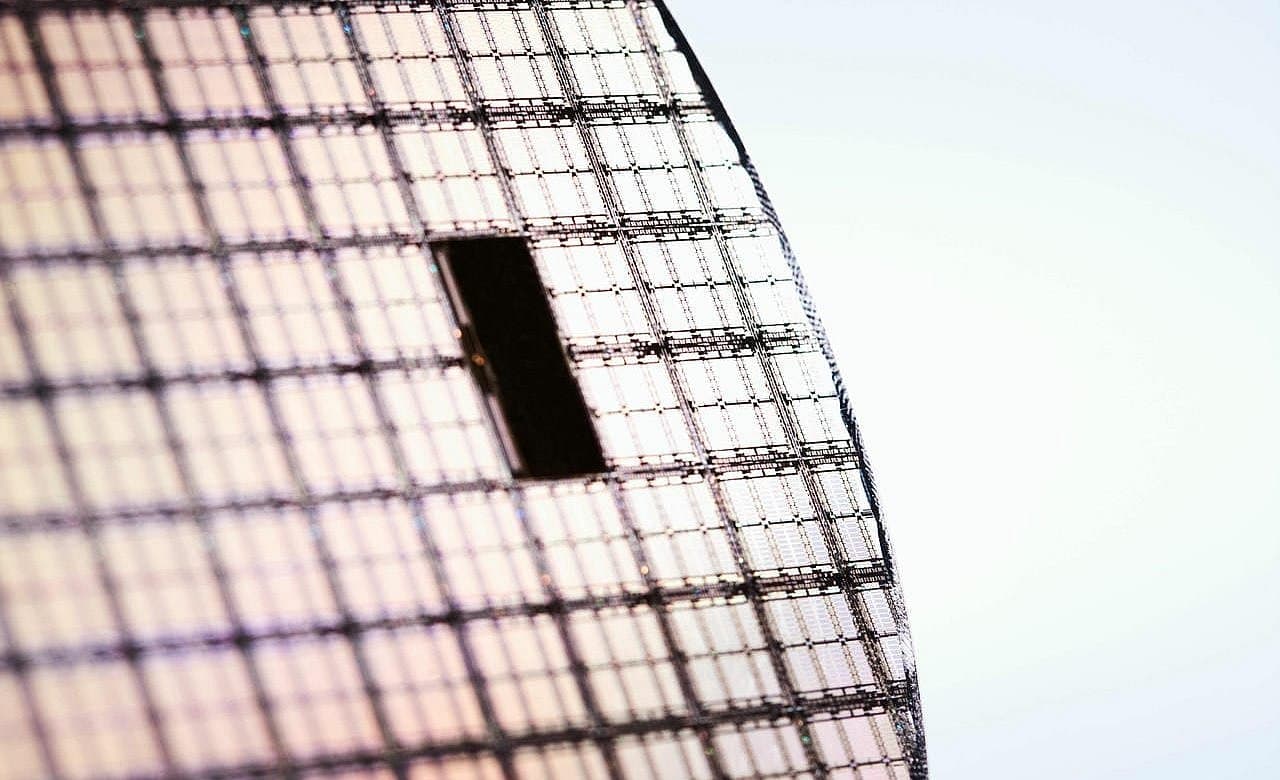

Special equipment for automated measuring and analysis of smallest structures, very thin coatings and multilayer systems on wafers with diameters up to 12 inches.

Key Benefits

- Fully automated.: Perfectly fitted for 24/7 use and smooth measuring processes

- Smart details for usability.: Integrated CCTV monitoring of the complete handling process

- Easy maintenance.: Large service hatches for access to individual components

- DPP+ digital pulse processor.: Shorter measuring times or improvement of standard deviation*

Description

Special device for automated measuring and analysis of smallest structures, very thin coatings and multilayer systems on wafers with diameters up to 12 inches.

¹ Significantly improved standard deviation and thus gauge capability or significantly reduced measurement time compared DPP to DPP+. ² Polycapillary optics, which are constantly being further developed. High-end capillary optics made by Fischer - the world's only manufacturer of X-ray fluorescence measuring instruments with its own polycapillary production.

The FISCHERSCOPE® X-RAY XDV®-μ SEMI is the optimal measuring solution for fully automated inspection of microstructures on wafers. The automated wafer handling and inspection process ensures a very high efficiency and enables error-free handling and measurement of wafers due to consistent inspection conditions through an encapsulated inspection environment. The powerful detector, microfocus tube Ultra and polycapillary optics for smallest measuring spots guarantee an outstanding measuring performance.

The automation solution is available as a pre-engineered solution. Benefit from an existing hardware and software design. Together we modify and adapt the automation device according to your requirements.

Perfectly fitted for 24/7 use and smooth measuring processes

Integrated CCTV monitoring of the complete handling process

Large service hatches for access to individual components

Shorter measuring times or improvement of standard deviation*

*compared to the DPP

No contamination of the wafers as well as constant measuring conditions

Automated measurements on predefined structures thanks to advanced pattern recognition technology

Our in-house manufactured polycapillary optics deliver outstanding measurement results with short measurement times

DPP+ for highest precision even with short measuring times

Standardized SECS/GEM communication

Microfocus tube Ultra with tungsten anode for even higher performance on smallest spots with µ-XRF

Silicon drift detector 20 or 50 mm² for highest precision

Peltier cooling

Polycapillary optics for particularly small measuring spots of 10 or 20 µm half-width

Compatible with delivery by OHT and AGV

4-fold changeable filter

Precise, programmable measuring table with vacuum wafer chuck

Coating thickness measurement and elemental analysis of

Do you have further applications? Then contact us!

Features

- DPP+ for highest precision even with short measuring times

- Standardized SECS/GEM communication

- Microfocus tube Ultra with tungsten anode for even higher performance on smallest spots with µ-XRF

- Silicon drift detector 20 or 50 mm² for highest precision

- Peltier cooling

- Polycapillary optics for particularly small measuring spots of 10 or 20 µm half-width

- Compatible with delivery by OHT and AGV

- 4-fold changeable filter

- Precise, programmable measuring table with vacuum wafer chuck

- Up to 50% ¹ increased performance thanks to DPP+

- Polycapillary optics Produced in-house & constantly developed²

- Unbeatable cost-benefit ratio

- Base metallizations in the nanometer range

- C4 and smaller solder balls

- Thin lead-free solder caps on copper pillars

- Extremely small contact areas and other complex 2.5D and 3D packaging applications

- Fully automated inspection of microstructures