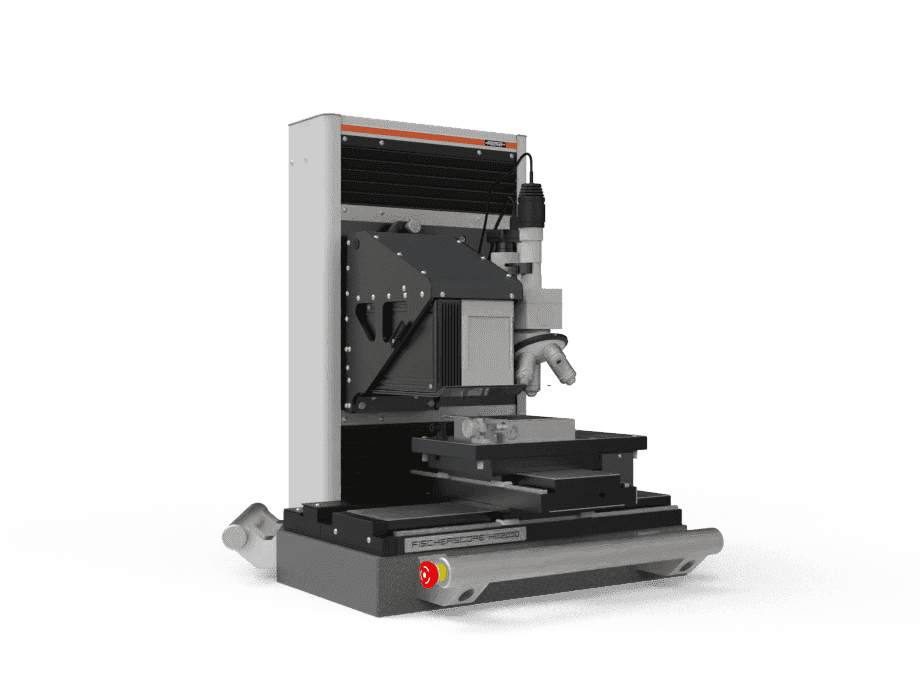

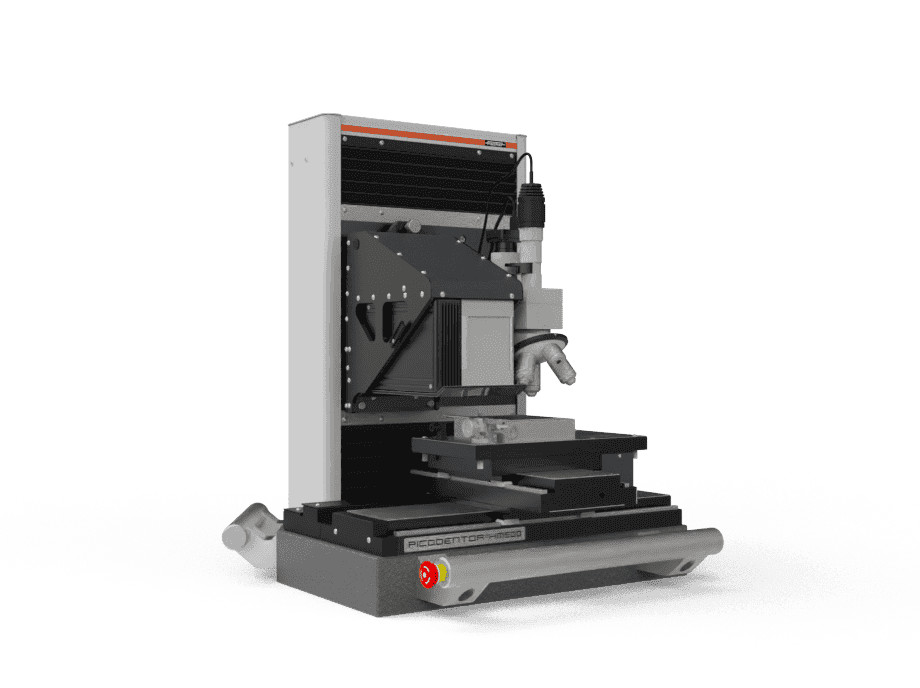

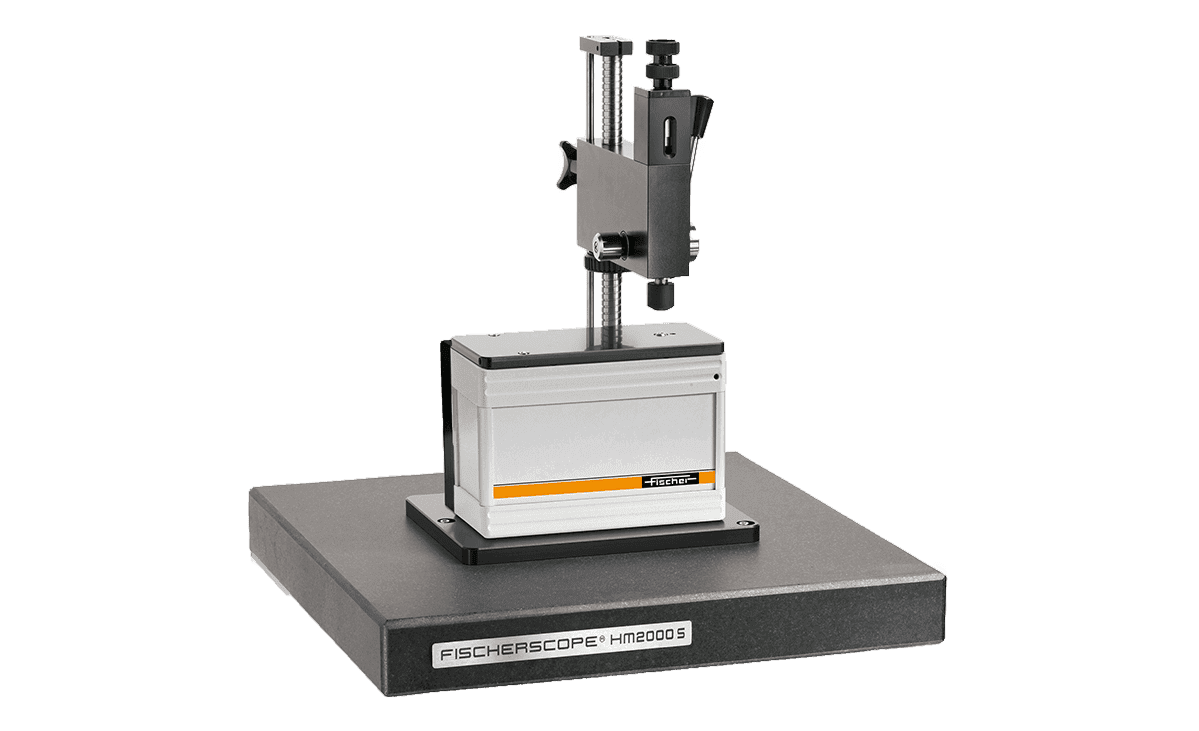

FISCHERSCOPE® HM2000 S

Your entry into nanoindentation.

Cost-effective entry-level instrument for microhardness determination of coatings in the micrometer range.

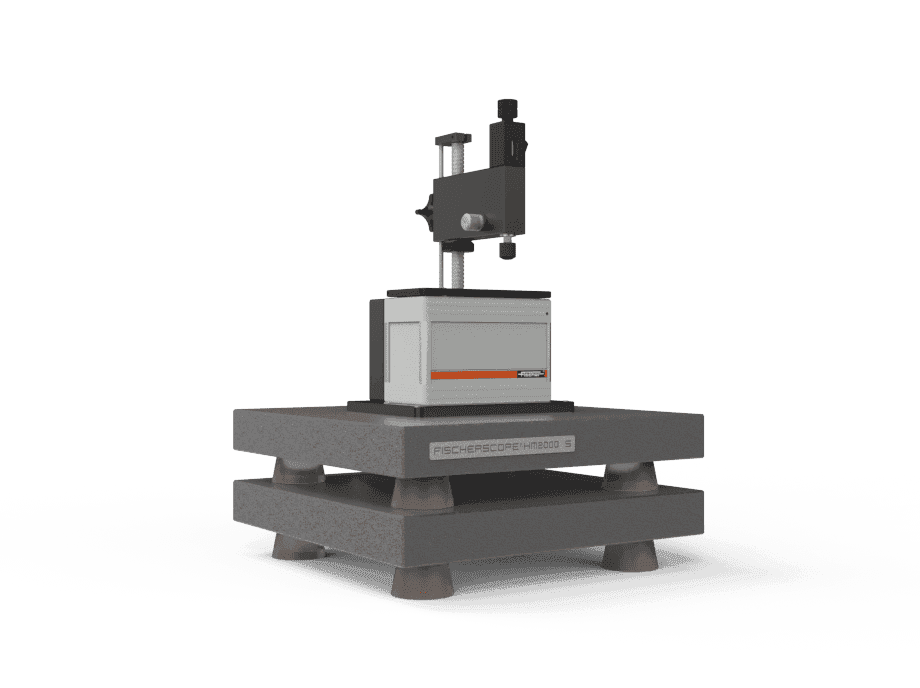

Key Benefits

- Quick-measure design.: Fast measuring without time-consuming sample preparation

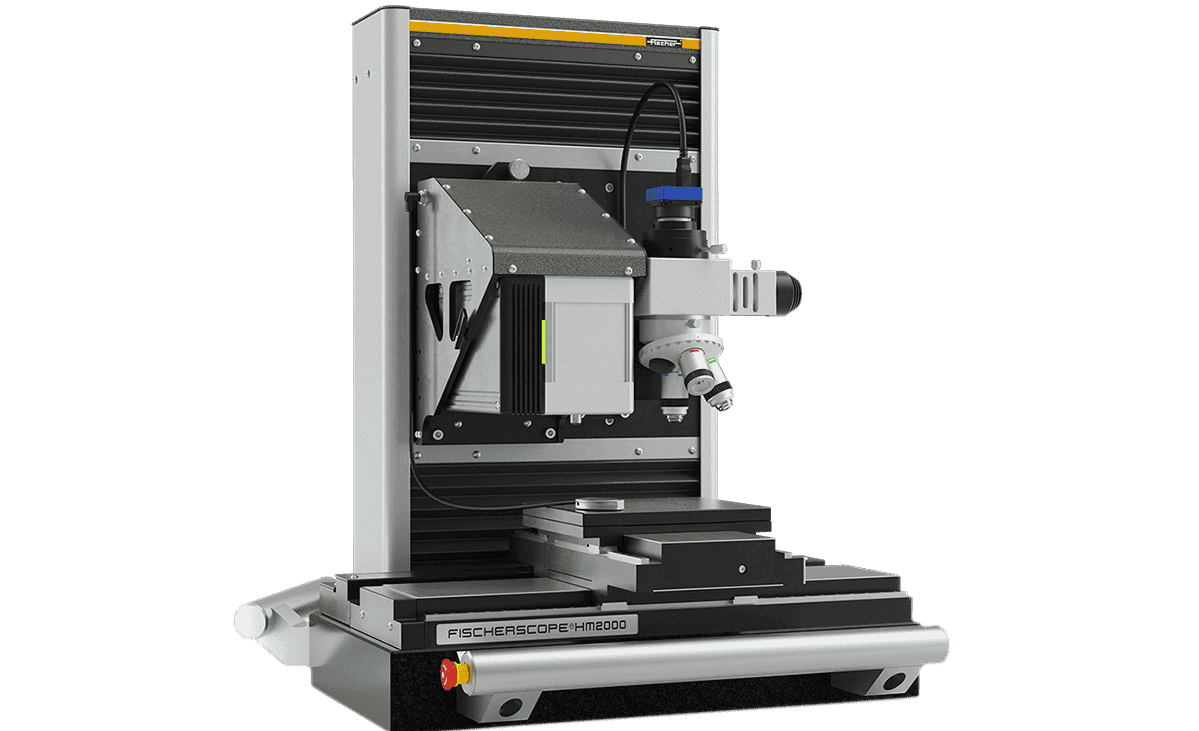

- Grows with you.: Upgradable to the automated HM2000 variant

- Balanced.: Optimal cost-benefit ratio

- Easy to use.: Intuitive operation with WIN-HCU® software

Description

Cost-effective entry-level instrument for microhardness determination of layers in the micrometer range.

Availability depending on region and country.

The cost-effective FISCHERSCOPE® HM2000 S hardness tester allows you to quickly and easily test the mechanical and elastic properties of surfaces, usually without sample preparation. This makes it ideal for laboratory and production use.

Fast measuring without time-consuming sample preparation

Upgradable to the automated HM2000 variant

Optimal cost-benefit ratio

Intuitive operation with WIN-HCU® software

Robust design for a particularly long product life cycle

Determining Martens and Vickers hardness, elastic indenter modulus, creep behavior according to DIN EN ISO 14577 and ASTM E 2546

Temperature stable: Possible measurements at constant temperatures over several hours

Powerful WIN-HCU® software for intuitive operation and evaluation

Testing of solid materials and coatings > 1 µm, test load range 0.1 - 2000 mN

Dynamic measurement mode for elastic parameters such as storage and loss module

Closed measuring chamber to avoid external influences (optional)

Indentor shapes: Vickers, Berkovich, carbide ball, Knoop or custom indentors

Programmable, high-precision measuring table for automated measurements

Do you have further applications? Then contact us!

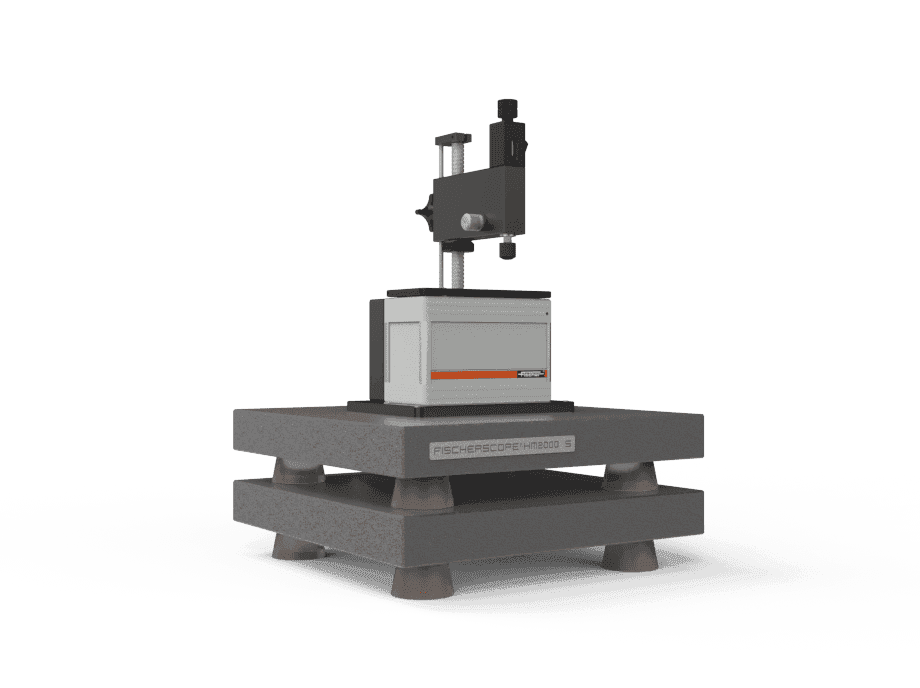

Features

- Determining Martens and Vickers hardness, elastic indenter modulus, creep behavior according to DIN EN ISO 14577 and ASTM E 2546

- Temperature stable: Possible measurements at constant temperatures over several hours

- Powerful WIN-HCU® software for intuitive operation and evaluation

- Testing of solid materials and coatings > 1 µm, test load range 0.1 - 2000 mN

- Dynamic measurement mode for elastic parameters such as storage and loss module

- Closed measuring chamber to avoid external influences (optional)

- Indentor shapes: Vickers, Berkovich, carbide ball, Knoop or custom indentors

- Programmable, high-precision measuring table for automated measurements

- Simplest and fastest sample preparation on the market

- Lowest cost device on the market

- Intuitive and simple use

- Measuring on test parts with simple geometry

- Lacquer, plastic or hard material coatings (PVD, CVD)

- Electroplating coatings (decorative, functional)

- Characterization of hard anodic coatings

- Materials especially for medical technology

- Coatings applied with plasma