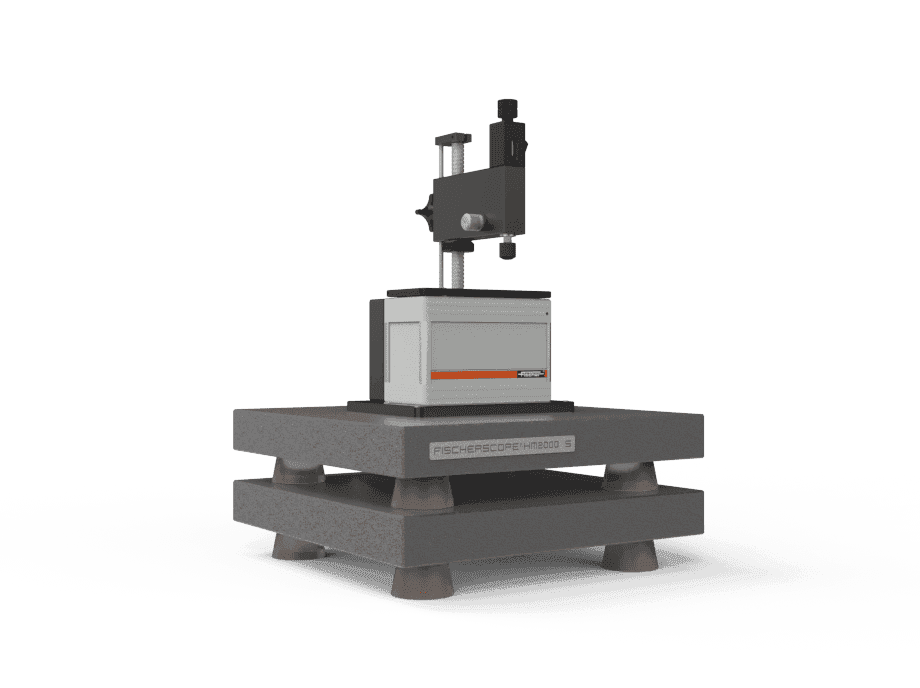

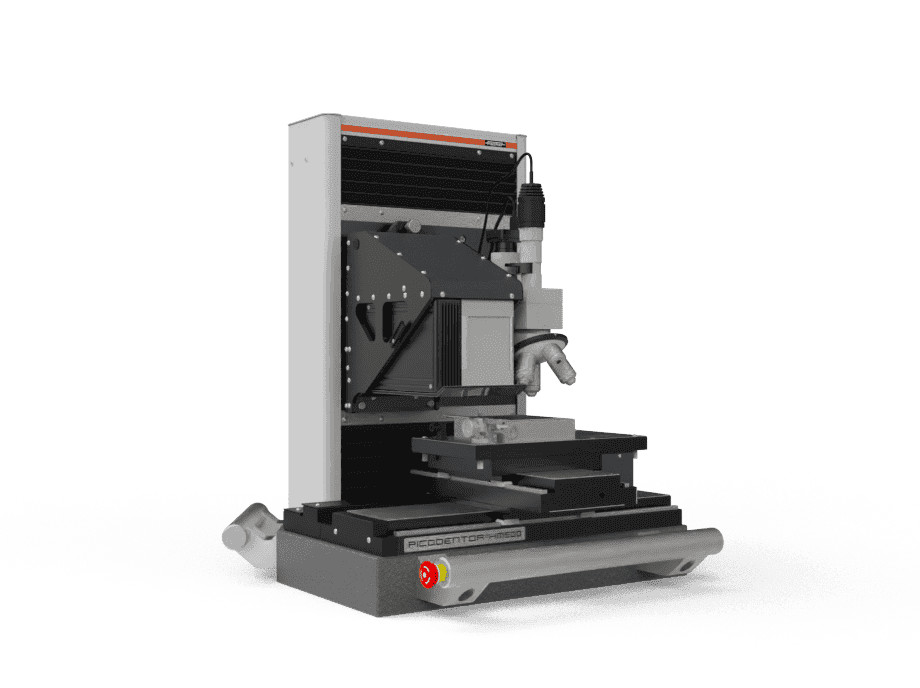

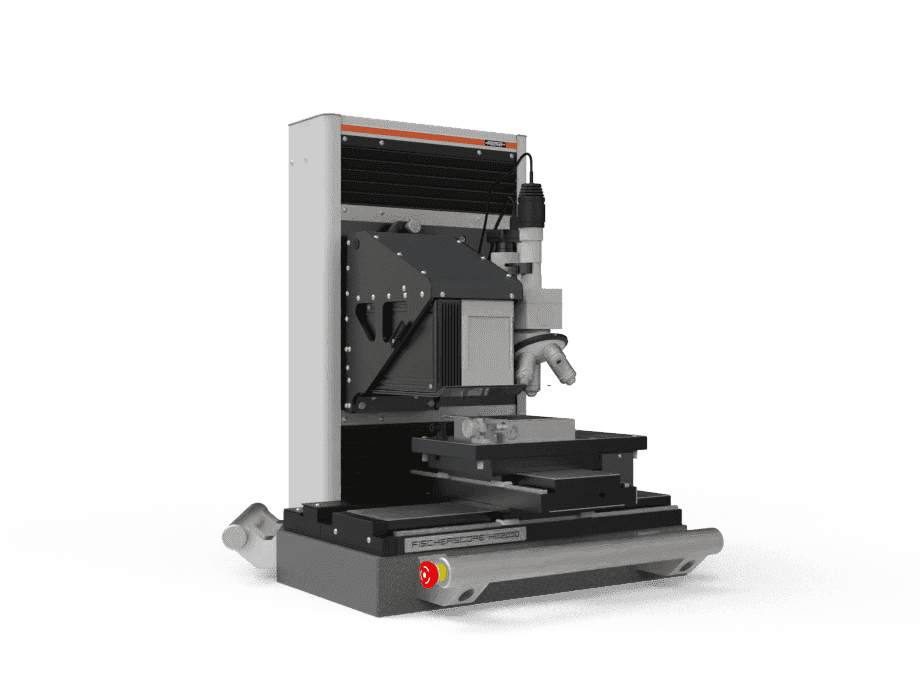

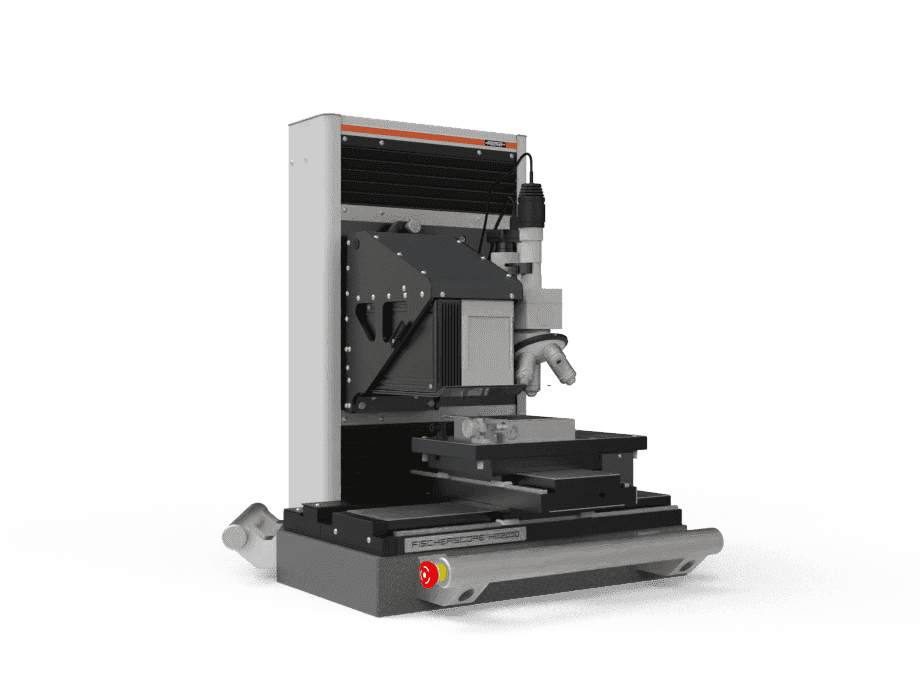

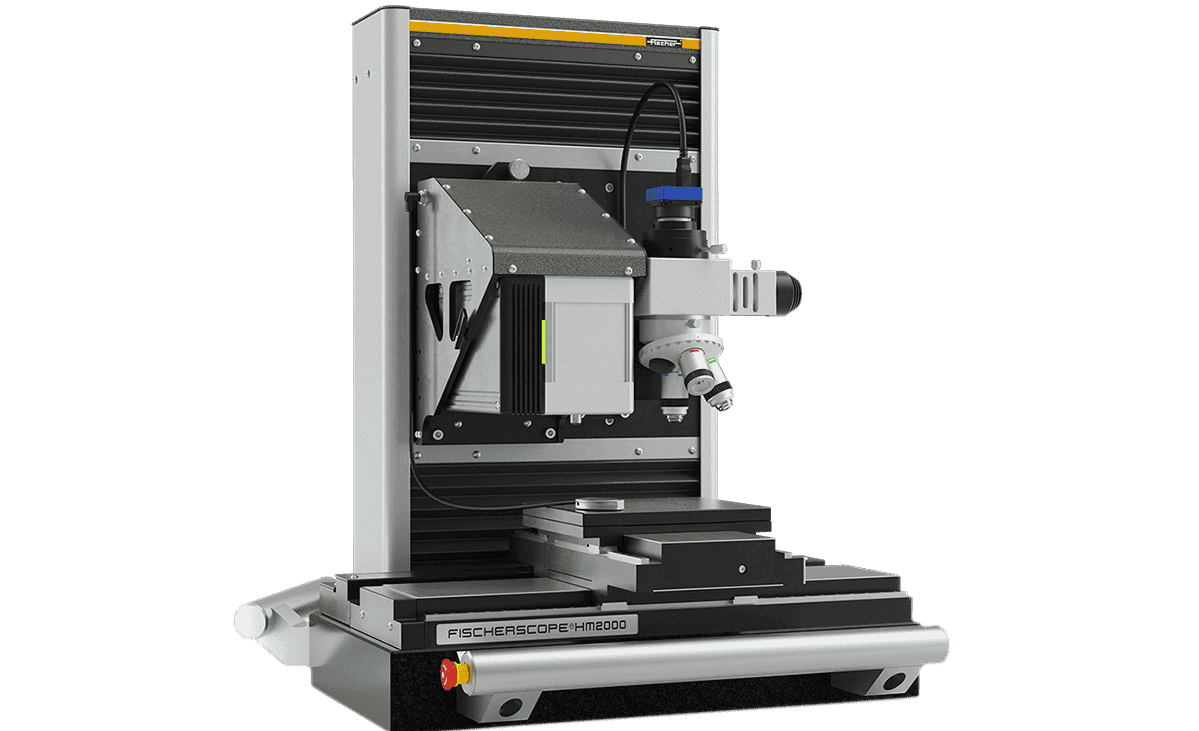

FISCHERSCOPE® HM2000

Nanoindentation for professionals.

Hardness measuring instrument for determining properties such as indentation hardness and the depth-dependent elastic indenter modulus – in the nanometer range.

Key Benefits

- Fast measurement.: The zero point is determined within only 30 seconds

- Modular design.: Customized designs or later upgrades to the instrument

- Quick-measure design.: Fast measurement without time-consuming sample preparation, even on dark surfaces

- Easy to use.: Intuitive operation with the software WIN-HCU®

Description

Reliable hardness measuring instrument for determining properties such as indentation hardness and the depth-dependent elastic indenter modulus – and all of that in the nanometer range.

Availability depending on region and country.

The FISCHERSCOPE® HM2000 reliably and precisely determines properties such as indentation hardness and elastic indenter modulus – in the nanometer range. The semi-automated measurement is fast and without complex sample preparation, which is why it finds its use in laboratory and production. The design of the measuring system ensures high dimensional stability, low temperature expansion and reduces the influence of vibrations. This way you are always on the safe side.

The zero point is determined within only 30 seconds

Customized designs or later upgrades to the instrument

Fast measurement without time-consuming sample preparation, even on dark surfaces

Intuitive operation with the software WIN-HCU®

Robust design for a long product life cycle

High sample throughput possible

Determining hardness and other material parameters according to DIN EN ISO 14577 and ASTM E 2546

Testing of solid materials and coatings > 1 µm, test load range 0.1 - 2000 mN

Fast measuring, zero point is determined within only 30 s

Measuring Vickers hardness, elastic indenter modulus and storage and loss modules

Temperature-stable and vibration-resistant: Possible measurements over several hours without external influences

Powerful WIN-HCU® software for intuitive operation and evaluation

Indentors: Vickers, Berkovich, carbide ball, Knoop or individual indentors

Integrated microscope with 4-fold, 20-fold and 40-fold objective for exact positioning of the measuring point

Expandable with heating table SHS200 as well as sound insulation box

Do you have further applications? Then contact us!

Features

- Determining hardness and other material parameters according to DIN EN ISO 14577 and ASTM E 2546

- Testing of solid materials and coatings > 1 µm, test load range 0.1 - 2000 mN

- Fast measuring, zero point is determined within only 30 s

- Measuring Vickers hardness, elastic indenter modulus and storage and loss modules

- Temperature-stable and vibration-resistant: Possible measurements over several hours without external influences

- Powerful WIN-HCU® software for intuitive operation and evaluation

- Indentors: Vickers, Berkovich, carbide ball, Knoop or individual indentors

- Integrated microscope with 4-fold, 20-fold and 40-fold objective for exact positioning of the measuring point

- Expandable with heating table SHS200 as well as sound insulation box

- Simplest and fastest sample preparation on the market

- Three available lenses

- Optical zoom of the sample

- Measuring the hardness and elasticity of paint layers, for example automotive paint

- Testing of anodized coatings

- Instrumented penetrant testing of hard material coatings, such as on tools

- Characterization of surfaces in research and development, e.g. hard chrome or ceramic coatings on medical implants

- Series testing in electroplating

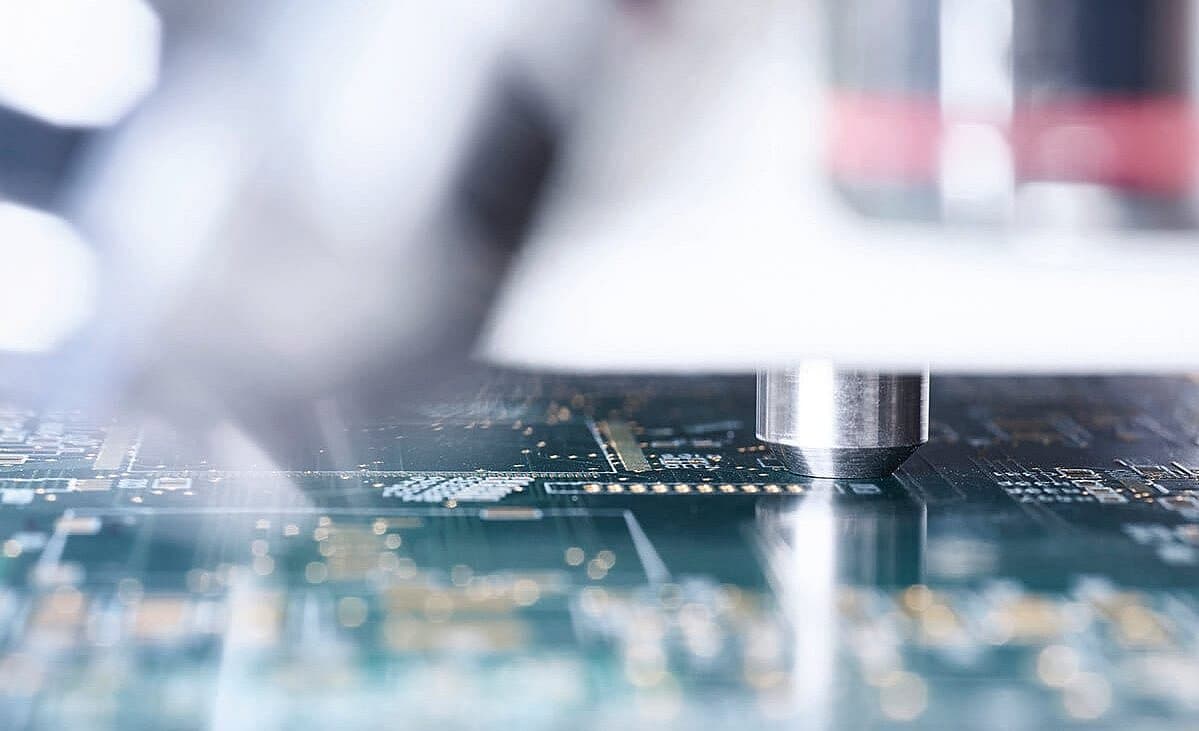

- Quality assurance of PCBs, for example testing of thin gold layers or insulating layers

- Hardness test on complex shaped parts, for example housings

- Characterization of composite materials

Documents

- AN018 Microhardness measurements of paint coatings shorten weathering tests0.24 MB

- AN019 Mechanical characterisation of lacquer coatings in automotive applications0.60 MB

- AN022 Determining the surface hardness of paint coatings – Pencil testing vs. instrumented indentation testing0.84 MB

- AN033 Microhardness tester for quality control of LCD spacers0.78 MB

- AN037 Mechanical characteristics of anodised coatings0.53 MB

- AN043 Determining mechanical properties of thin CuSn6 foils0.78 MB

- AN049 Mechanical characteristics of conformal coatings0.57 MB

- AN054 Determining the mechanical properties of hard coatings used on machining and milling tools0.61 MB

- AN056 Nanoindentation on wear-resistant DLC coatings applied to engine components0.64 MB

- AN057 Measuring the micro-hardness of tooth enamel in dentistry0.76 MB

- AN058 Micro-hardness testing of dental composites0.59 MB

- AN079 Wear resistance of dies for production of coins0.65 MB

- AN082 Using nanoindentation to characterise the hardness of coatings on weight-bearing medical implants0.55 MB

- AN083 Effect of colour pigments on the hardness of thermoplastics at different temperatures0.64 MB

- AN087 Measurement Application of carbon fiber reinforced plastic (CFRP)2.52 MB

- AN090 Determination of the heat influence on plastics and coatings using the dynamic measurement mode1.23 MB

- Product overview: Complete portfolio3.17 MB

- Product overview: Microhardness3.53 MB